[NGW Magazine] Decarbonising the networks

Projects designed to decarbonise natural gas grids by adding hydrogen are making progress across Europe. NGW spoke to Cadent, which is aiming to add hydrogen to the gas supply of 2mn customers.

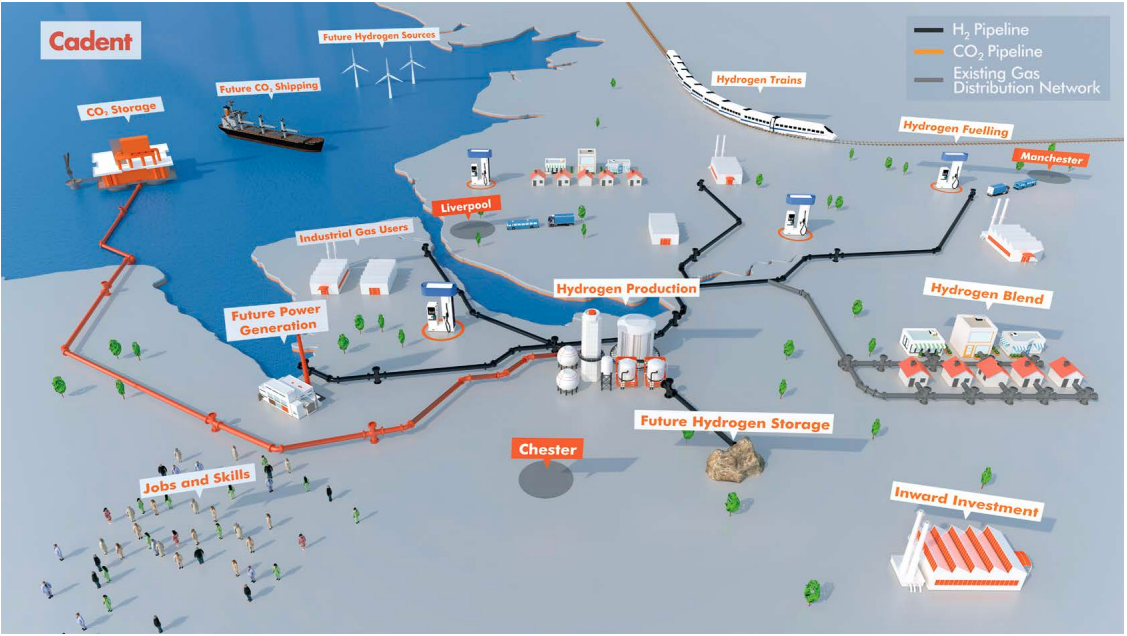

UK distribution grid operator Cadent is planning to inject hydrogen into the gas grid in northwest England. Its HyNet project is by far the most ambitious European project to decarbonise the grid, and such a scale is only possible if methane – rather than surplus renewable power – is used, according to its project manager, Andy Lewis.

Andy Lewis speaking at the HyNet North West Launch (Credit: Cadent)

Decarbonising the gas grid is inevitably going to move up the priority list of European policy makers over the coming years as they struggle to meet emissions targets. While wind, solar and other renewables are making good progress in decarbonising the power sector, and electric cars have the potential to deal with transport, there has been little progress so far in heating and cooking which relies heavily on gas supplied into peoples’ homes and workplaces.

Electrification is looking too expensive, leaving hydrogen or biogas as the only commercially viable alternatives. In the UK, estimates for the cost of electrification have been £10,000-£20,000 ($13,000-$26,000) per home, plus installing six times the current generating capacity of about 55 GW and associated transmission lines to meet peak winter heating demand, according to a recent National Grid report.

Hydrogen, in particular, is popular with established energy companies as it can make use of existing assets, which also makes it relatively cheap.

Most hydrogen pilot projects use surplus renewable power to produce the hydrogen from electrolysis, but the process takes vast amounts of energy and installed capacity is not yet at a point where sufficient excess exists to implement hydrogen production at scale.

Reforming methane to produce hydrogen, on the other hand, is much cheaper and can more easily be done at scale given current resources, according to Lewis, the project-manager at Keele University’s HyDeploy research project and the HyNet project itself.

“The best way to produce hydrogen on a large scale in the short term is by reforming natural gas; reforming is far cheaper than electrolysis,” he said. “Then in the longer term, as more renewables come online, we may eventually be able to produce significant quantities from the surpluses. But for the time being, only reforming can produce the volumes required to make any sort of difference [to CO2 emissions levels]. The capital required for renewables right now would be too much, and [the UK] has targets to meet.”

The HyNet project aims to produce 5-6 TWh/yr of hydrogen to mix at up to 20% concentration into the gas supply of 2mn customers – including major industrial users – compared with just a few hundred households in the case of competing European projects. The latter are all based on renewables and electrolysis (see below).

Eventually the UK could be supplied by a network of hydrogen plants linked to offshore carbon capture and storage (CCS), according to DNV’s VP Business Development for UK and West Africa Graham Bennett. “Hydrogen’s energy density is a third that of methane – so you would be using about the same amount of methane as today or slightly more,” he said.

Additional costs

Lewis said that it was essential to start the ball rolling on CCS, which is needed to store the carbon produced as a by-product of methane reduction: “The Committee on Climate Change, Imperial College London and other experts have all emphasised the need to employ CCS to ensure the least-cost route to decarbonisation. We need to store 20mn mt/yr of CO2 in the 2030s, and we have to start somewhere. So, we have to do something in the 2020s. We need to see a full chain CCS system working,” he said.

HyNet’s carbon would be stored in Eni’s Hamilton field. “By keeping storage very close to the source of CO2 we keep the costs down, and these are further offset by the money saved by not having to decommission the field... We still need government support for this first-of-a-kind project, but CCS represents by far the best option in value for money terms – HyNet could remove 1mn mt of carbon from the heating system by the mid-2020s.”

Overview of the HyNet Project (Credit: Cadent)

The depleted Hamilton sour gas field in the East Irish Sea can store up to 100mn mt of CO/CO2, with potentially another 1bn mt at Centrica’s nearby and much larger Morecombe Bay sour gas fields (see separate interview with Engie's Didier Holleaux).

An announcement from the UK’s CCS task force on the deployment pathway for CCS is expected towards the end of this year, although government CCS policy swings in the past will keep some potential investors wary, he added.

The weakest link

Extensive research at Keele on appliances, as part of the HyDeploy project, is ongoing, but indicates that almost all domestic and industrial appliances are safe at hydrogen concentrations of 20% or below. “Since 1996 EU GAB regulations have required appliances to work on mixes of up to 23% hydrogen, although we are still physically testing every model.” He said that while higher concentrations were fine with some appliances, over 20% would begin to require replacement of the weakest boilers; “so we have to stop there for the time being.”

“The H21 project is assessing whether we can inject 100% hydrogen into the existing network – it can’t be done now, but could happen in the future… [The UK has] a world class gas network that we should continue to use in the future.”

The hydrogen appears to behave predictably in the gas network. “Four injection points should be sufficient for the HyNet project… The key thing is that it stays mixed with the natural gas – what you don’t want is a slug of hydrogen hitting your appliance. It doesn’t seem to float to the top; it disperses well within the natural gas... Fundamentally hydrogen is a smaller molecule, so it has the potential to leak out more quickly, but as we change [from metal] to polyethylene pipeline we are effectively future-proofing our network,” said Lewis. Recent US studies suggest 5% to 15% hydrogen by volume is acceptable in well maintained systems, while current European regulations allow between 0.1–12% hydrogen. Some countries and US states, such as Germany and California, are also planning stand-alone grids to supply pure hydrogen to the transport sector.

European collaboration

Lewis said HyNet and HyDeploy shared their research findings on hydrogen’s behaviour in networks and appliances with other major European projects that aim to mix hydrogen with natural gas in the grid - although all of these plan to use surplus renewables, rather than methane reforming, and are on a far smaller scale.

The main collaborating projects are Engie’s GRHYD project in Dunkerque, France, which is looking at putting 10% hydrogen into the gas system to heat 200 homes plus a clinic, as well as fuelling a fleet of buses. Engie says ‘power-to-gas’ is an activity “at the crossroads of its businesses.”

German utility E.ON is also involved in two power-to-gas projects in Germany, one in Falkenhagen and one in Hamburg-Reitbrook, and “they can already accept 10% hydrogen into quite a bit of their network,” said Lewis. A third major renewable/electrolysis project is Gasunie’s Amaland project in the Netherlands.

“We share research and are in regular contact particularly with the French project, which is ahead of us in some respects. A lot of learning is shared,” said Lewis. “We see that the gas grid has a role to play in decarbonisation, and we are trying to demonstrate that and secure the role of our asset.” HyDeploy partners include Keele, the government Health and Safety lab, Northern Gas Networks, ITM and Cadent. Cadent also leads the HyNet project consortium.

Jeremy Bowden

Carbon capture and storage: re-purposing technology

The technology for capturing carbon from a stream of gases is many decades old, as it was developed from gas sweetening technology. It has for example been used at the Sleipner field offshore Norway.

The system depends on flowing an alkaline liquid in one direction and the acid carbon dioxide in the other to meet it, where the gas is absorbed. The liquid is then heated up so that the carbon dioxide is boiled off and collected, while the rest of the vapour is condensed and fed back to start the cycle again. The heating of the liquid would normally cost nothing at an industrial site: waste heat from other processes, such as power generation, would be diverted to the boiler.

That is the principle on which the ABB-Imperial College plant functions, using as the solvent monoethanol amine (MEA), which is the simplest one to use, according to Colin Hale of Imperial College who jointly runs the plant. But there are complications as the creation of MEA itself produces CO2 and the whole process is energy-intensive.

With a capacity of 500 metric tons/year, the £1mn plant, in the South Kensington campus, is used to train undergraduates in flow process technology, in a ten-year project that was agreed in 2012. It replaced an older plant that had been operating there for educational purposes. The team is working on ways to make the new plant more efficient, including making it work at lower temperatures for the same absorption rate. Nevertheless, this is the best near-term commercial technology, Hale told NGW.

The two owners benefit differently: Imperial has from ABB much of the control and diagnostic instrumentation and software and hardware it needs to teach the operation of stream processes to its students, using a number of different approaches based on actual companies’ protocols; and ABB is associated in the minds of the students with work they might want to do after graduation through brand awareness.

There are bigger projects in operation, including Petro Nova’s $1bn plant in West Virginia in the US, which strips the C02 – which could form a fifth of the total – out of the flue gas from coal-fired power generation. That uses proprietary technology, making cost and efficiency comparisons difficult. But while the plant cost is very high, Hale says that the value comes from transporting the CO2 for injection into an oilfield. This has raised output at West Ranch, Virginia, from a few hundred barrels of oil/day to 15,000 b/d.

Visitors to the Imperial College site have included British and Singaporean policy makers who need to understand more about CCS; and also senior Australian politicians. CCS was made one of the preconditions of the Gorgon LNG project, offshore Australia.

In the UK, Hale said, Drax is developing technology that, if successful, will actually reduce the amount of carbon dioxide in the atmosphere by burning biofuel for power generation and then capturing the CO2 after combustion. The solvent, being developed by C-Capture, is still to be tested though.

William Powell