Green Hydrogen: just around the corner? [GasTransitions]

With resurgent interest in hydrogen as a key element (yes, pun) of a prospective 100% renewable energy economy, we see headlines about the imminence of green hydrogen’s arrival on the global energy scene. “The new kid in town”. Truth or hype? Some of both?

It’s been noted that in many small but significant niche markets, hydrogen from electrolysis of water already “out-competes” hydrogen made from fossil fuels. Advocates observe that volume production and technical advances are reducing the cost of electrolysis equipment; they predict that lower costs for electrolysers, in combination with still-falling costs for renewable electricity, will soon make green hydrogen cost-competitive with “gray” hydrogen across the board. It will be cheaper than “blue” hydrogen, which captures and sequesters the CO2 otherwise emitted in production of gray hydrogen from fossil fuels.

Sense or nonsense?

I can’t say categorically that the above prediction is nonsense. There are plausible paths by which it might come to pass – at least if one takes a liberal view of what constitutes “soon”. But there are some strong caveats to consider. Starting with the distinction, often ignored, between “green” hydrogen and electrolytic hydrogen.

An estimated 5% of world hydrogen production today is electrolytic. That portion is what’s consumed in the many “small but significant niche markets” mentioned above. Three factors favor electrolytic production: (1) local demand that is not large enough to justify the capital expense of a reforming plant, (2) the high cost and inconvenience of trucking in liquid or pressurized hydrogen purchased on the merchant gas market, and (3) a requirement for pure “reagent grade” hydrogen that can be made locally on demand. But out of all the electrolytic hydrogen produced in response to those factors, almost none of it is “green”.

Green hydrogen, as it’s usually thought of, is electrolytic. However, electrolytic hydrogen is not necessarily green. For the hydrogen to qualify as green, the electricity used to produce it must itself have a very low carbon footprint. Almost all electrolytic hydrogen produced today uses electricity from the grid, and almost all grid electricity has a carbon footprint that is too high for electrolytic hydrogen made from it to qualify as green.

Aside from places like Norway, with its vast hydroelectric power capacity, or France, with its clean nuclear capacity, the greenest grid power one is likely to find might average 50% from zero-carbon resources, and 50% from power plants burning fossil fuels. The best case for the latter would be all natural gas, with an average thermal efficiency of 40%[1]. The energy content of the methane in natural gas is 55.6 MJ per kg; at 40% conversion efficiency, that’s 22.2 MJ or 6.18 kWh electricity per kg of methane.

Modern commercial electrolysers need about 50 kWh of electricity to produce one kg of H2. Thus, for our hypothetical “pretty clean” energy grid with half of its generation carbon-free and the rest from natural gas, it still takes 0.5 ✕ 50/6.18, or a tad over 4 kg of methane to produce one kg of H2. 4 kg of methane upon combustion for power generation becomes 11 kg of CO2 released to the atmosphere. Not exactly low carbon.

For the alternative of reforming hydrogen from steam and natural gas, the chemical formula is:

CH4 + 2H2O(g) + heat => CO2 + 4H2

The minimum heat required is 165 kJ/mole of methane, or 10.3 MJ/kg. If the heat is supplied from some external source, it only takes 2 kg of CH4 to produce one kg of H2. There’s a process that has been demonstrated in a lab to achieve just that. A technical paper published in Nature Energy, titled “Thermo-electrochemical production of compressed hydrogen from methane with near-zero energy loss” details how. I reported on it in an Energy Central article in 2018. The process looks very promising, but it’s not yet commercial.

If the heat for the reforming reaction above is supplied through combustion of a portion of the natural gas input, then it takes 180 grams of natural gas to supply the required heat at perfect efficiency. That’s a theoretical 2.18 kg CH4 per kg H2. More realistically for processes widely deployed, it’s more like 2.5 kg of CH4. Still, that’s a lot better than the >4 kg of CH4 to produce 1.0 kg of electrolytic hydrogen using “pretty clean” grid power.

For electrolytic H2 to beat gray H2 on carbon emissions, the power grid from which the electrolysers draw must be more than just “pretty clean”. It must be at least 70% carbon-free if the remaining 30% is supplied by natural gas. If the remainder is supplied by coal, 85% of the grid’s energy must be from carbon-free resources. And that’s disregarding the carbon and environmental footprint of building and deploying solar panels and wind farms.

This result points up the achilles heel of electrolytic hydrogen as an energy carrier. The low 40% round-trip efficiency of P2G2P (power-to-gas-to-power) substantially increases the amount of primary generation needed to meet overall demand. The carbon footprint of all that additional power generation (2.5 kWh for every kWh supplied by electrolytic hydrogen) transfers over to whatever power is generated from electrolytic hydrogen. Until the grid has already reached a very low carbon intensity, the additional energy demand created by electrolytic hydrogen production will increase rather than reduce fossil fuel consumption.

A fair analysis?

At this point, I can hear green hydrogen enthusiasts crying foul. After all, the whole point of green hydrogen is to make productive use of renewable energy that would otherwise be lost. When available supply from wind and solar temporarily exceeds current demand, the excess is used to produce hydrogen rather than being curtailed. In that case, 100% of the electricity used to produce hydrogen is free of carbon emissions. It’s unfair then to apply the overall carbon intensity of the grid to green hydrogen production.

That argument is valid. If green hydrogen is produced only from renewable energy that would otherwise be curtailed, then its production does not result in any marginal increase in carbon emissions. The hydrogen qualifies as truly green. The problem is that the required scenario is more limiting than fans of green hydrogen are generally willing to recognize.

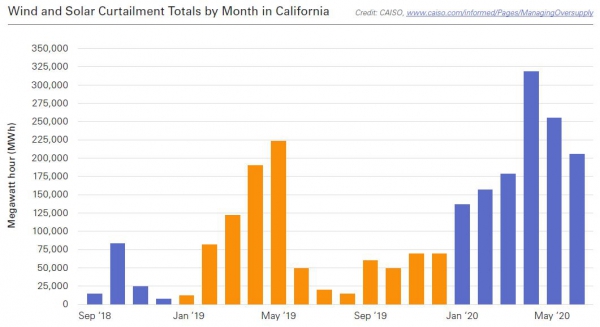

Even in the particular regional grid that has achieved the highest penetration of variable wind and solar resources in the western hemisphere, curtailment is rare. The transmission grid operated by the California ISO (CAISO) serves 80% of California and parts of Nevada. According to California’s energy.gov website, total electrical energy consumption for the service region in 2019 was 259.5 TWh. According to CAISO’s own data, the total amount of wind and solar generation curtailed in 2019 was 0.961 TWh. That’s only 0.3% of the 2019 total electricity consumption in the service area.

That 0.3% is also the amount of electricity that would have been available for production of green hydrogen in 2019, had green hydrogen production capacity been in place and able to use all of the available surplus. Given the low 40% round-trip efficiency of hydrogen for energy storage, the 0.961 TWh of surplus energy put into hydrogen storage would subsequently have returned 0.384 TWh of zero-carbon electricity -- just 0.15% of overall consumption.

The problem with these numbers isn’t so much that the surplus wind and solar available on the grid for producing green hydrogen is currently such a small fraction of overall consumption. Grid penetration by wind and solar resources will presumably continue to rise – at least in California – and will lead to non-linear increases in number and durations of episodes of surplus. But the amount of surplus available within those episodes will be quite variable. The average in each episode will get larger, but the episodes will likely follow the same seasonal distribution seen in the CAISO chart below. Surpluses will be concentrated in the months of spring, when production from renewables is high while summer air conditioning load has yet to kick in.

The upshot of these considerations is that the CF (capacity factor) for electrolysis equipment for green hydrogen production from surplus wind and solar energy on the grid will be quite low. If operation is limited to surplus production, the CF will initially be less than 1%. It will take quite some time to rise to double digits. What does that say about economic feasibility?

The capital cost of electrolysers is currently running in the ballpark of $50,000 per hourly kg of hydrogen production capacity. At a high CF of 50%, lifetime 20 years, and discount rate 6%, the cost of capital would add $1.00 per kg to the cost of electrolytic hydrogen. That translates to an added 5 cents per kWh of fuel cell output, on top of 2.5 times the cost of grid electricity powering the electrolysers. But if electrolyser CF is only 5% instead of 50%, that added 5 cents per kWh jumps ten-fold to a crippling 50 cents per kWh.

A CF of 5% is very low, but it’s not unrealistic for electrolysis that’s limited to operation from surplus renewable energy on the grid. As noted above, surplus RE episodes are not spread evenly over the course of a year. They’re skewed seasonally. The wind and the intermittent resources producing temporary surpluses have low CFs themselves. Add in the consideration that 50% would be the maximum CF for electrolysers on a grid that spends half the time generating hydrogen from surpluses and half the time using the produced hydrogen to balance shortages, and we see that achieving even a 5% CF for electrolysers would require moderately heavy overbuilding of intermittent renewables on the grid.

What about dedicated renewables?

A potential way to raise the capacity factor of equipment and boost the economic prospects for green hydrogen is to power its production from RE resources that are dedicated to the job. They would not be integrated into the power grid, and the energy they would supply for hydrogen production would be cheap and carbon-free. It would still be intermittent and seasonally variable, but its overall capacity factor would be far better than if green hydrogen production were restricted to using only surplus carbon-free energy from the grid.

Indeed, Saudi Arabia, in partnership with Air Products & Chemicals Corp., just announced plans for a giant green hydrogen project to be powered by dedicated 4 GW of wind and solar capacity [q.v.]. Beginning sometime in 2025, it is slated to produce 650 tonnes of green hydrogen daily. The plan is not to export the hydrogen directly, but to use it to make ammonia. Ammonia has high value for fertiliser, and is much easier to transport and store than hydrogen. But when power generation is needed, it’s easy to catalytically decompose ammonia back into hydrogen and nitrogen.

Analysis of the economic and environmental effects of this type of system gets a little tricky. We suddenly need to distinguish between the effects on the global system, vs. the effects on project owners and developers.

Merely leaving the RE resources that power hydrogen production isolated from the grid does not eliminate the negative consequences of using grid power to produce electrolytic hydrogen. At least it doesn’t if connection to the grid was an option. There’s no essential difference between taking power from a dedicated resource vs. connecting that resource to the grid and taking power from the grid. Hence, if hydrogen electrolysis is drawing more power from its dedicated resource than what would be available to it as surplus if the dedicated resource were connected to the grid, then the energy the electrolyser is using isn’t really green. Isolation of the resource creates an “opportunity cost” for not being able to use its output to reduce carbon emissions on the grid. However, the opportunity cost is not charged to the project owners and developers; it’s effectively externalised to the grid where it’s somebody else’s problem. It’s still a real cost to the system.

In practice, things are even more complicated. The logic above applied “if connection to the grid was an option”. But maybe it wasn’t an option – or not an affordable option. The resource might be a solar farm in the middle of the Sahara Desert, or a wind farm floating in deep water far offshore. In that case, its energy output would otherwise be stranded, and the hydrogen produced truly qualifies as green. Many of the green hydrogen pilot projects going forward around the world seem to follow that model.

Green hydrogen pilot projects using dedicated wind and solar resources are a good way for nations and corporations to advertise their commitment to fight climate change. But beyond their PR value, the projects will likely generate at best modest returns on capital invested. On the other hand, by stimulating the market, they should help to reduce the future cost of electrolysis. That could make other green hydrogen projects easier to justify. Whether they otherwise make sense as clean energy investments is a different issue.

The high costs of transporting and storing hydrogen render it a low-value product in relation to the energy needed to produce it. The wind and solar farms that will be powering the electrolysis tie up capital, but are effectively selling their output to the hydrogen production side of the operation for next to nothing. “Next to nothing” is what electrolytic hydrogen requires if the hydrogen output is going to compete with hydrogen from fossil fuels. The operation might not be losing money directly, but it will have at best a mediocre ROI. It won’t be the sort of thing that ordinarily attracts the interest of businesses and investors.

The Competition

There are various ways that the economic prospects for green electrolytic hydrogen might be improved. Breakthrough technical developments are always possible. Breakthroughs might suddenly drop the capital cost of electrolysis equipment or improve the round-trip efficiency of P2G2P. However, I see no such developments on the near horizon.

A more fundamental problem for electrolytic hydrogen is the competition. For bulk hydrogen production, the chief competition, as noted above, is reforming from fossil fuels. But regardless of how it’s produced, hydrogen itself faces competition from other energy storage technologies. The low round-trip efficiency of hydrogen in P2G2P is a serious handicap. That’s true whether the ‘G2P’ part of the cycle is for dispatchable power generation on the grid or for power to FCEVs. Lithium-ion batteries deliver more than twice the output of stored energy per unit of input energy: 85% vs. 40%. Hydrogen can deliver longer range for FCEVs and faster refueling, but the > 2:1 efficiency advantage of batteries is hard to overcome.

For long term energy storage on the scale needed to deal with extended periods of adverse weather – not to mention seasonal variability – stored hydrogen or stored ammonia remain the top contenders to replace fossil fuels. But the hydrogen needn’t be produced by electrolysis of water. That’s a costly and energy-intensive way to go. The energy cost to produce H2 from biomass or fossil fuels is far lower. And capital cost of equipment tends to correlate with the energy cost of a process.

Incremental gains in wind and solar production and deployment technology will likely lead to continuing declines in the cost of as-available energy from variable renewables. It’s also likely that the specific capital cost for electrolysers and associated equipment will decline – especially if production rises enough to justify investments in more advanced production lines. Lower capital costs will lighten the economic penalty from operating at low duty cycles from surplus renewable energy. Taken together, these developments make it plausible that green hydrogen can indeed become cost-competitive with hydrogen produced from fossil fuels in current SMR process trains. However, is it reasonable to expect that other methods for producing hydrogen will be standing still?

It’s well to keep in mind that there is already a substantial world market for hydrogen. It’s small compared to what it could become if hydrogen really takes off as an energy carrier. However, it’s quite large enough to justify serious R&D efforts worldwide to bring down costs. There’s interest in a wide range of alternative approaches for hydrogen production. One is the highly efficient thermo-electrochemical process referenced earlier, but there are many others. Too many, in fact, to list here and try to survey. But they all share one feature in common: they all require substantially less electrical energy per kg of produced hydrogen than commercial processes for electrolysis of water.

The bottom line

“Great expectations” for a clean hydrogen economy have come and gone before. Will the new hope for hydrogen find solid anchorage this time around, or will it drift back into yesterday’s buzz? I’m no prophet, but I expect that the story will settle out somewhere in between.

Despite the impressive advances that Toyota and other Asian automakers have made in finally bringing reasonably practical fuel cell vehicles to market, I’d be really surprised if FCEVs ever manage to overtake battery EVs in the mass automotive market. For heavy equipment where fuel cost is secondary to high availability and extended operating time off grid, hydrogen has strong advantages – especially if married to ammonia for storage. Ammonia and HFC’s are also naturals for long duration backup power to microgrids. And they’re a good bet for long distance electrified air transport.

What I don’t have much faith in is the vision of green hydrogen made from surplus wind and solar as the solution for intermittency. Massive overbuilding is required before the concept begins to pencil out economically and technically. Even German and California taxpayers have limits on the subsidies they’re willing to support.

Blue hydrogen, on the other hand, looks promising. Barring a sudden, unlikely turnaround in our attitudes toward nuclear power, hydrogen made from fossil fuels with CCS seems the best bet for replacing natural gas in backing installed wind and solar capacity. It could potentially move us quickly and economically to a zero-emission power sector. However, that will require those environmental groups currently opposed to CCS to come around.

Whether they will or not remains to be seen.

Roger Arnold is a former software engineer and systems architect. He studied physics, math, and chemistry at Michigan State University's Honors College and worked variously at IBM, Boeing Aerospace, AT&T, and about a dozen smaller companies and startups in San Diego and Silicon Valley. After retiring from professional life as a systems architect, he founded the Silverthorn Institute, a private research group focusing on clean energy technologies, energy efficiency, and sustainability. He is a regular contributor to the U.S.-based website Energy Central.

[1] A combined cycle gas turbine (CCGT) operated in baseload mode is capable of doing better. However, when backing up variable renewables, losses from throttling, cycling through start-up / shut-down, and extended operation away from the optimum design point take a toll. Add in transmission losses and the fact that many of the plants used in that manner will be simple combustion turbines rather than premium combined cycle units, and 40% net efficiency is a generous estimate.