Gas Transition News [GasTransitions]

Large green hydrogen facility planned in Oman

The Belgian company DEME Concessions is planning to build a large-scale green hydrogen plant with Omani partners in Duqm, Oman. “The facility will significantly contribute to the decarbonisation of the regional chemical industry in Oman,” said DEME, “as well as providing green hydrogen and/or derivatives (such as green methanol or ammonia) to international customers in Europe, for example in the Port of Antwerp.”

The envisaged electrolyser capacity for a first phase is estimated between 250 and 500 MW, which is much higher than any existing electrolyser plant in the world at this moment. Following this first phase, upscaling of the installation is foreseen, DEME has said. The advantage of the location in Duqm is the availability of cheap renewable energy (solar and wind), as well as large, accessible sites (on- and offshore). A feasibility study will be carried out by consulting firm Roland Berger. A final investment decision is expected in 2021.

RWE and BP announce Germany’s first hydrogen network

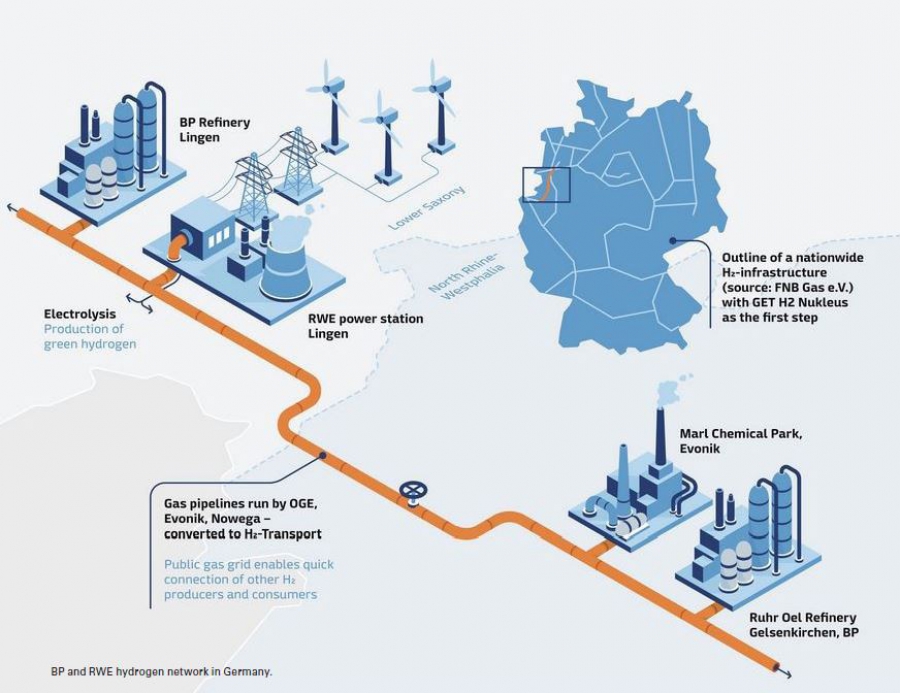

Germany's largest energy company RWE, oil company BP, chemicals producer Evonik and gas grid operators OGE and Nowega have announced the construction of the country's first publicly accessible hydrogen distribution network. The project aims to connect producers of green hydrogen with industrial clients from 2022 on, "provided this is economically viable,” the companies have said.

The hydrogen network, dubbed GET H2, will have a length of 130 kilometres and will be built in the country's northwest to supply industry customers in the states of Lower Saxony and North Rhine-Westphalia. The companies have promised it will be open for third parties at "transparent prices."

An electrolysis plant with a capacity of 100 megawatts in the town of Lingen will provide the hydrogen through a grid that is going to be "converted to 100 percent hydrogen," the companies said. Additionally, existing cavern storages will be used along the hydrogen pipelines for storage. The project should "pave the way to technological leadership" for Germany in hydrogen production and facilitate the transition to climate-neutral industrial production in the country.

Japanese companies to coordinate hydrogen demand

In Chubu, Japan, a Hydrogen Utilisation Study Group has been formed by ten private companies. The aim is to create demand for hydrogen and build a hydrogen supply chain in the Chubu region. The companies include Toyota Motor Corporation, Air Liquide Japan, Chubu Electric Power, Toho Gas, Nippon Oil & Energy, Sumitomo and Mitsubishi Chemical.

The Japanese government has designated hydrogen as one of the key elements for sustainable energy, and drawn up a “Strategic Roadmap for Hydrogen and Fuel Cells” to realise a “Hydrogen Society”, notes the Study Group in a press release. The roadmap aims to achieve the production of 300,000 tons of green hydrogen by 2030. A modest amount considering that e.g. U.S. production of hydrogen today is 10 million tons per year.

According to the Study Group, although many activities are carried on the production side, there is not enough coordination taking place on the demand side. The Group Conduct will undertake a study of potential hydrogen demand in the Chubu region, such as in the power generation and oil industries, and in mobility, and attempt to remove bottlenecks to the development of a green hydrogen market.

Meanwhile, at the site of the abandoned Fukushima nuclear plant, Toshiba has built a 10 MW solar-powered hydrogen production unit. According to the company, the plant, called the Fukushima Hydrogen Energy Research Field (FH2R) can produce up to 1200 newton meters of hydrogen per hour.

Research: hydrogen fuel production made 25x more efficient

As Science Daily tells the story, there are two reasons why hydrogen is not used more widely today. First, because it is highly flammable and leaks very easily from storage tanks. Second, “it is not found in quantities sufficient for cost-effective utilization. Hydrogen atoms must be extracted from molecules like methane or water, which requires a large amount of energy.” In other words, it’s not competitive.

For decades, scientists have been working towards a cheap, efficient, and safe way to produce hydrogen fuel, writes Science Daily. “One of the most promising methods to achieve this is through solar-driven processes, using light to speed up (or "catalyze") the reaction to split water molecules into oxygen and hydrogen gas. In the 1970s, two scientists described the Honda-Fujishima effect, which uses titanium dioxide as a photocatalyst in hydrogen production.”

Building on this research, a team of Japanese researchers led by Prof Ken-ichi Katsumata of Tokyo University of Science, tried “a cheaper, more readily available semiconductor catalyst for this reaction, with the hope to increase its efficiency even further, reducing the production costs and safety of hydrogen fuel.” Their study published in Chemistry: A European Journal indicates that, “by using a form of rust called α-FeOOH, hydrogen production under Hg-Xe lamp irradiation can be 25 times higher than titanium dioxide catalyst under the same light.”

"We were really surprised at the generation of hydrogen using this catalyst," said Professor Katsumata, "because most of the iron oxides are not known to reduce to hydrogen. Subsequently, we searched for the condition for activating α-FeOOH and found that oxygen was an indispensable factor, which was the second surprise because many studies showed that oxygen suppresses hydrogen production by capturing the excited electrons."

The team “confirmed the production mechanism of hydrogen from water-methanol solution using a 'gas-chromatography-mass-spectrometry' method, showing that α-FeOOH was 25 times more active than the titanium dioxide catalyst used in previous research, supporting stable hydrogen production for more than 400 hours.”

More research will be required to optimize this process, notes Science Daily. Prof Katsumata elaborates: "The specific function of the oxygen in activating light-induced α-FeOOH has not been unveiled yet. Therefore, exploring the mechanism is the next challenge."

Engie invests in membrane reactor technology

French energy giant ENGIE has announced, through its corporate venture capital arm ENGIE New Ventures, a strategic investment in H2SITE. Headquartered in Bilbao, Spain, H2SITE is a spinoff created by Tecnalia research and technology center and Eindhoven University of Technology. According to a press release from ENGIE, it aims at “commercializing a membrane reactor based system able to produce high purity hydrogen, on customer’s premises, from various hydrogen carriers such as methane in particular biomethane and ammonia, etc.”

The H2SITE technology platform “aims at addressing the issue of decentralized production, transport and storage of hydrogen with a compact and cost effective on-site solution, and is based on a one-step industrial process combining membranes in a reactor. This disruptive technology was identified and assessed by ENGIE through diverse collaborative research projects.”

In addition to a minority investment in the capital of H2SITE, ENGIE, through its research center ENGIE Lab CRIGEN, has forged a R&D cooperation partnership with Tecnalia and Eindhoven University of Technology to further develop emerging applications of this technology contributing to transition towards carbon neutrality.

Hydrogen Taskforce announced in UK, led by BP, Shell

In the UK a Hydrogen Taskforce has been set up, describing itself as “a cross-industry coalition of leading organisations focused on conveying a unified voice to the UK Government.”

It aims to “secure support and investment for hydrogen in the UK, across its many applications, to enable the UK to become a world leading hydrogen economy. The Taskforce will bring clear, consistent advocacy to UK Government and capture the interest of key decision makers to promote the hydrogen economy in the wider energy system, economic and political environment.”

The Taskforce, based in Birmingham, is supported by BP, Shell, BNP Paribas, Arup, Storengy, BOC (Linde), Baxi, ITM Power, Cadent and DBD. It has produced a report urging the government to commit £1 billion over the next spending review period to hydrogen projects. It also urges collaboration to build 100 hydrogen refuelling stations for road transport. It also foresees that gas boilers can be converted to run on hydrogen in the future.

German sector coupling projects endangered

Up to 100 “sector coupling” projects in Germany, such as power-to-gas and other green hydrogen projects, risk failure, according to the economic committee of the Bundesrat, Germany's council of state governments. In a statement, the committee said that integrating the power sector with heating, industry and transport was "indispensable" to reaching Germany's climate targets but many projects currently risk becoming "stranded assets" when they reach the end of their operating grants.

According to a report on Clean Energy Wire, “the committee recommended that the federal government creates an experimental clause, which could be used to exempt temporary and geographically limited projects from expenses such as electricity tax or grid fees, in order to make them more economically competitive.

The committee's recommendation was based on a study by the Institute for Climate Protection, Energy and Mobility (IKEM) in Berlin, which showed that experimental clauses could help projects and plants overcome economic challenges without establishing "a new funding regime". IKEM’s Simon Schäfer-Stradowsky welcomed the committee's decision saying it would "allow projects in sector coupling to test new technologies and business models under shielded legal but also real market conditions and, above all, to introduce them to the market."

German research institute projects 50-80 GW electrolysis capacity in 2050

The Fraunhofer Institute, a prestigious research institute in Germany, has published a hydrogen roadmap (in German), which projects an electrolysis production capacity of 50 to 80 GW by 2050 in Germany alone. To reach this level, writes Clean Energy Wire, “annual growth rates in the double-digit megawatt range must be achieved immediately, and in the 1 GW range by the end of the 2020s.”

The technology of producing green hydrogen with renewable energy through electrolysis will become "a decisive industrial policy component in Germany, not only for the production of the hydrogen required in this country, but also as a flexibility option in the German power grid and as a core technology for the international export market," the research institution says. German manufacturers in electrolysis and fuel cells could gain added value of about €32 billion, based on an estimate of the global installed electrolysis capacity reaching 3,000 GW in 2050, says Fraunhofer.

The German government regards green hydrogen as a solution to some of the energy transition's most difficult challenges, particularly for use in industry and heavy transport. The German government is working on a highly anticipated hydrogen strategy, which has been postponed because of the corona crisis. According to Clean Energy Wire and other sources, the government “has scrapped provisions for also using hydrogen as a fuel for heating, as too much energy is lost in the transformation process and more efficient alternatives exist”.

New hydrogen storage technology deployed in Australia

The Manilla Solar Project, a partnership between Manilla Community Renewable Energy and Providence Asset Group in Australia, will use an advanced hybrid battery storage system called H2Store, which was developed at University of New South Wales by Professor Kondo-Francois Aguey-Zinsou and his team at the School of Chemical Engineering.

“The H2Store technology is a compact and transportable hydrogen storage solution. It’s an effective way to store and generate renewable energy, mitigate the fluctuation of renewable generation and increase confidence in the security of supply,” said Aguey-Zinsou in a press release.

The solar project combines battery storage with the hydrogen storage system. The project is expected to provide a model for sustainable energy that can be replicated by other communities.

H2 store technology uses metal hydrides to store hydrogen. This allows for higher density and lower pressure storage, making it possible to store hydrogen at a smaller scale. According to the researchers, the amount of energy stored per unit of space is greater than in conventional lithium-ion batteries.

Shell’s Dutch Oil and Gas R&D lab replaced by Centre for Sustainable Geo-Energy

The new Centre is a unique field lab built on top of a 400 metres deep well which can be used to conduct geothermal research by interested parties. It includes hydraulic presses of 300 and 400 tonnes, pressure vessels of up to 1,000 bar and piping systems for pumping in and testing fluids. Underground conditions can be realistically imitated to determine how materials and components behave under high pressure or at high temperatures at depths of kilometres.

The Netherlands has a target to meet a quarter of its heat demand with geothermal energy by 2050, but it is finding it difficult to expand its geothermal capacity. Projects are encountering many technological obstacles as well as physical limitations. TNO is working on a multi-lateral horizontal drilling technology to boost production from marginal geothermal reservoirs.

Research: new technology can reduce costs of blue hydrogen

There is a lot of debate on the comparative costs of blue and green hydrogen. It is generally assumed that the cost of green hydrogen will go down and at a certain point will be cheaper than blue. For this reason, Christian Weinberger, Hydrogen Coordinator at the European Commission, stated at a conference recently that “blue hydrogen is a dead-end street”. (See the report on the World Hydrogen Fuels Summit elsewhere in this magazine.)

There are two problems with this argument. First, the question is how fast it will be possible to scale up the production of renewable energy to meet hydrogen demand in a future energy system that will need molecules to function efficiently. The requirements are daunting, as this example from Germany makes clear. Secondly, the assumption is that costs of blue hydrogen will not be able to be reduced. But is that so?

Blue hydrogen will not be able to make use of the economies of scale which electrolysis can benefit from, that much is true. But improvements may still be possible in the carbon capture and storage processes. Researcher Schalk Cloete who works for research institute SINTEF in Norway wrote a paper recently in which he discusses next-generation technologies for the capture of CO2 based on “chemical looping” which have the potential to greatly reduce costs.

The technology investigated by Cloete is called Gas Switching Reforming (GSR). This reforms natural gas to syngas and separates out hydrogen in much the same way as the steam methane reforming technology used for most global hydrogen production today. The primary difference is that all CO2 emissions are inherently separated by the process. The produced hydrogen can either be combusted to producer power during times of low renewable energy output or directly sold as hydrogen during times of high renewable energy output. According to Cloete, GSR produces power for about half of the time and hydrogen for the other half at a very competitive sales price of €1.67/kg.